1. The choice of stepper motor torque

1. The choice of stepper motor torque

The holding torque of a stepper motor is similar to the “power” of a traditional motor. But the physical structure of stepping motors is completely different from AC and DC motors, and the output power of the motor is variable base on speed, current, and input voltage.

Generally speaking, if the needed torque is below 0.8N.m, choose nema8(20x20mm), nema11(28x28mm), nema14(35x35mm), nema16(39x39mm), nema17(42x42mm); if the torque is about 1N.m, choose the nema23 stepper motor. When the torque is several N.m or more, it is necessary to choose a stepper motor of nema34, nema42, and other specifications.

2. The choice of stepper motor speed

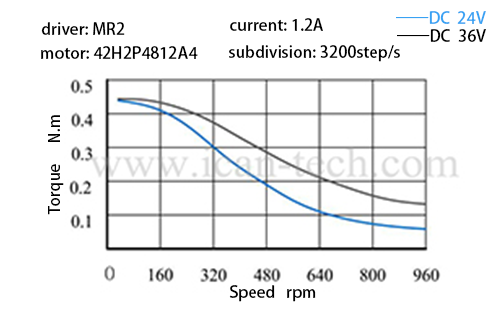

The output torque of the motor is inversely proportional to the speed.

That is to say, the torque of the stepping motor at low speed(a few hundred rpm) is high, but it is small when the stepper motor runs at high speed (1000 rpm-9000 rpm). For example:

Of course, some working conditions require high-speed motors, and the coil resistance and inductance of the stepping motor must be measured. Choose a motor with a smaller inductance, as a high-speed motor, can obtain a larger output torque. Conversely, when low speed and high torque are required, the inductance and the resistance should be larger.

3. Choose for the use environment of stepper motors

The special stepping motor is waterproof and oil-proof and is used on some special occasions. For special-purpose motors, it is necessary to select targeted ones. Customization is available for special usage.

4. Selection of the number of phases of the stepper motor

Generally, the stepper motor phase is not paid attention to customers. In fact, the more phases there are, the smaller the step angle can be made, and the smaller the vibration during work. In most cases, two-phase motors are chosen. In a high-speed and high-torque working environment, it is more practical to choose a three-phase stepper motor.

5. Special specifications selection according to the actual situation

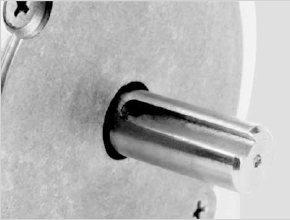

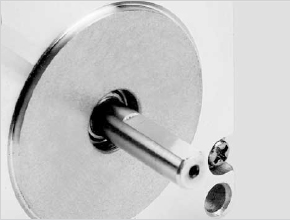

Special specifications of stepper motors, for example, the diameter, length, lead screw, and direction of the output shaft can be customized.

6. Selection of no-load starting frequency of stepper motor

The no-load starting frequency of a stepper motor, usually called “idling frequency”. If it is required to start and stop frequently in an instant, and the speed is about 1000 rpm (or higher), it is usually necessary to “accelerate the start”. If you need to start directly to achieve high-speed operation, it is better to choose a reactive or permanent magnet motor, because the “idling frequency” of these motors is relatively high.

ICAN Tech provides one-to-one before and after service, if you have any questions about model selection, contact us freely and we will reply to you in 12hours.

没有评论:

发表评论